Scan QR

Overview

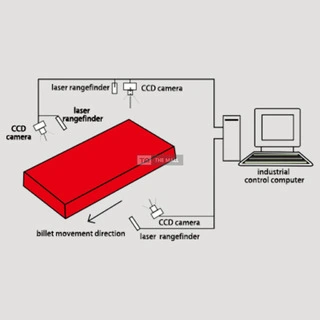

The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optica...

Scan QR

Overview

The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system.

The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system.

The measuring principle of the system

On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system.

The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection.

The main technical requirements

1. Width range of the inspected cast product: 120~2000 mm

2. Length range of the inspected cast product: 1000~20000 mm

3. Thickness range of the inspected cast product: 35~400 mm

4. Steel billet moving speed: < 3.5 m/s

5. Billet running speed: <6.5m/min

6. Temperature of the measured steel billet: 0~850 °C

7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm

8. Fixed weight accuracy: 0.8‰ (temperature model verification)

9. Quality inspection check: 1‰